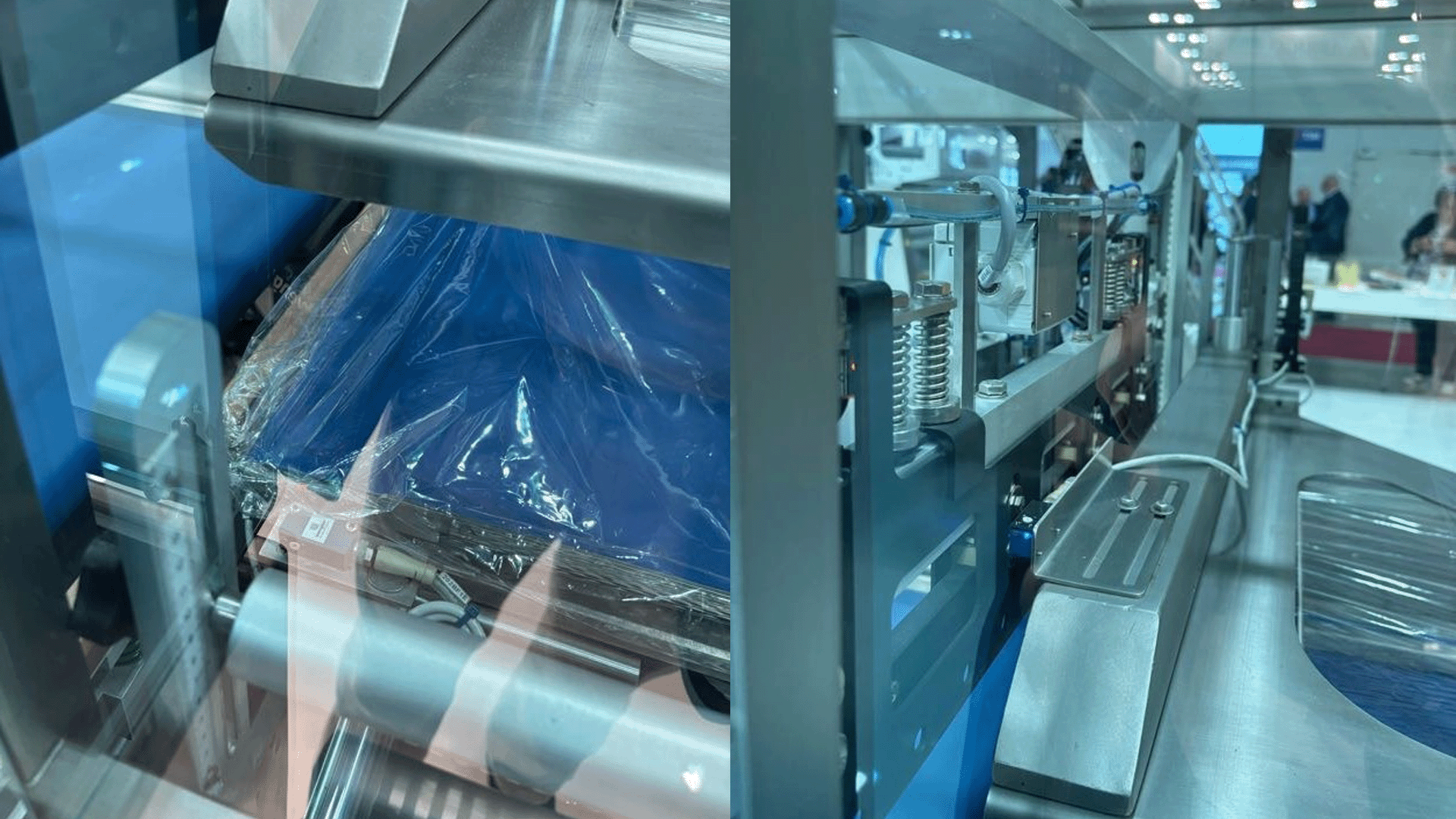

The detection of transparent materials plays a central role in food and pharmaceutical packaging. Particularly with thin or irregularly stretched films, precise detection is crucial to ensure the quality of the packaging and avoid production errors. Retro-reflex sensors offer a robust and application-specific solution for this.

Transparent plastic films pose a particular challenge for many optical sensors. Low light reflection, wrinkling or different material thicknesses often lead to unreliable switching signals. In high-speed systems, this can result in false detections that have a direct impact on process reliability and system availability.

The retro-reflex sensors from wenglor are specially designed to meet these requirements. They work with a reflector that returns the emitted light. As soon as the film enters the beam path, it changes the signal, ensuring reliable detection even with very thin or irregularly stretched films.

The teach-free technology used enables automatic adjustment to different material properties without the need for manual parameterization. This reduces the commissioning effort and ensures stable results even with changing batches or different film types.

Reliable detection of transparent films is a key factor for quality assurance in food and pharmaceutical packaging. Retro-reflex sensors with teach-free technology offer a user-friendly and robust solution that avoids incorrect packaging and ensures high efficiency even under demanding production conditions.

Job title