Automation has long been a central component of modern production environments. Rising energy prices, scarce raw materials and the increasing need for sustainable production are driving companies to digitally optimize their processes and make them more efficient. Highly developed measurement and sensor technologies play a decisive role in this. They provide precise data to control production steps, ensure quality and make targeted use of resources. In optical distance measurement in particular, reliable detection of even the most challenging surfaces is the basis for stable processes. Industrial applications place high demands here: Polished metals, transparent plastics or highly radiant objects require sensors that are both powerful and innovative.

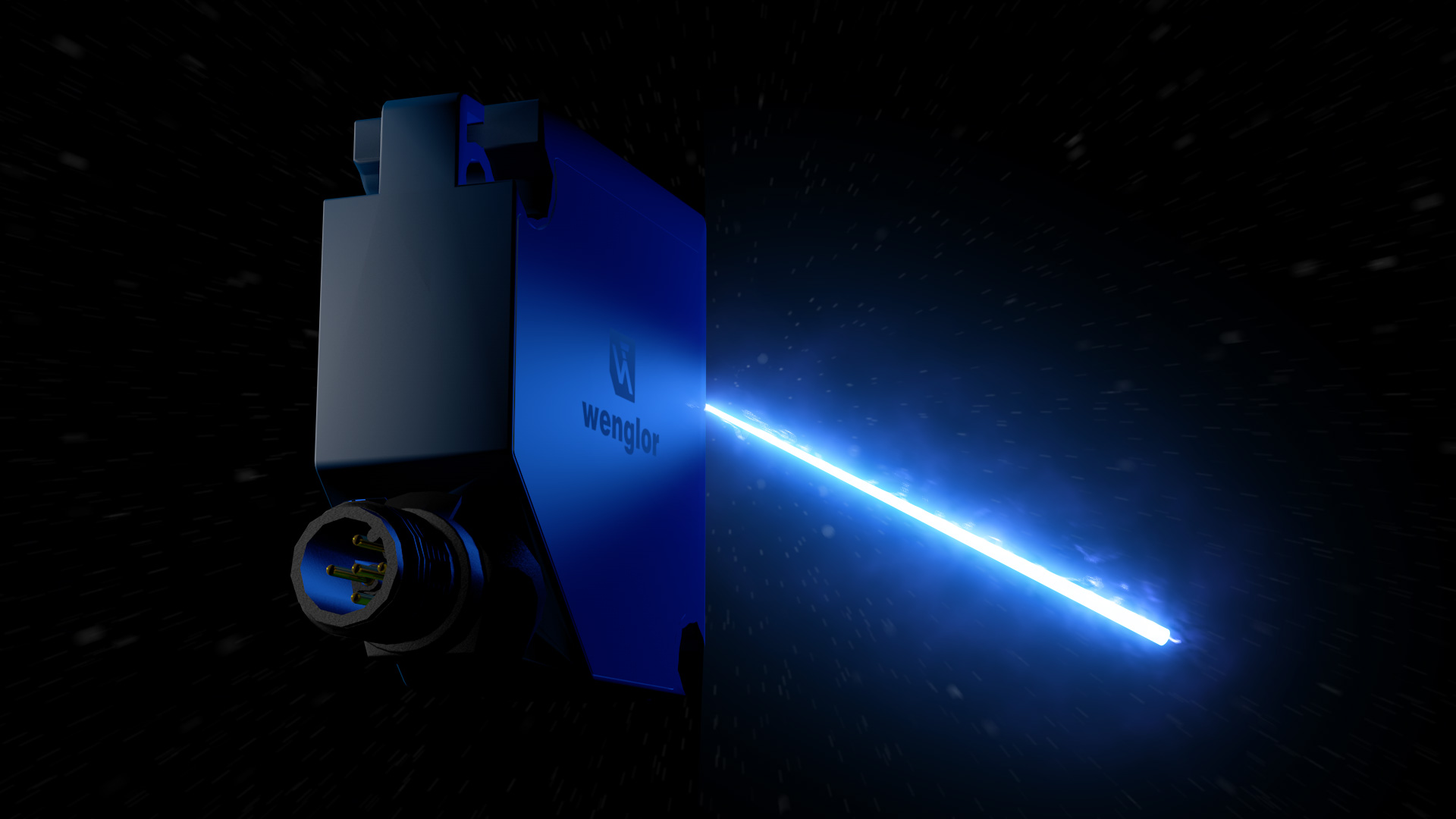

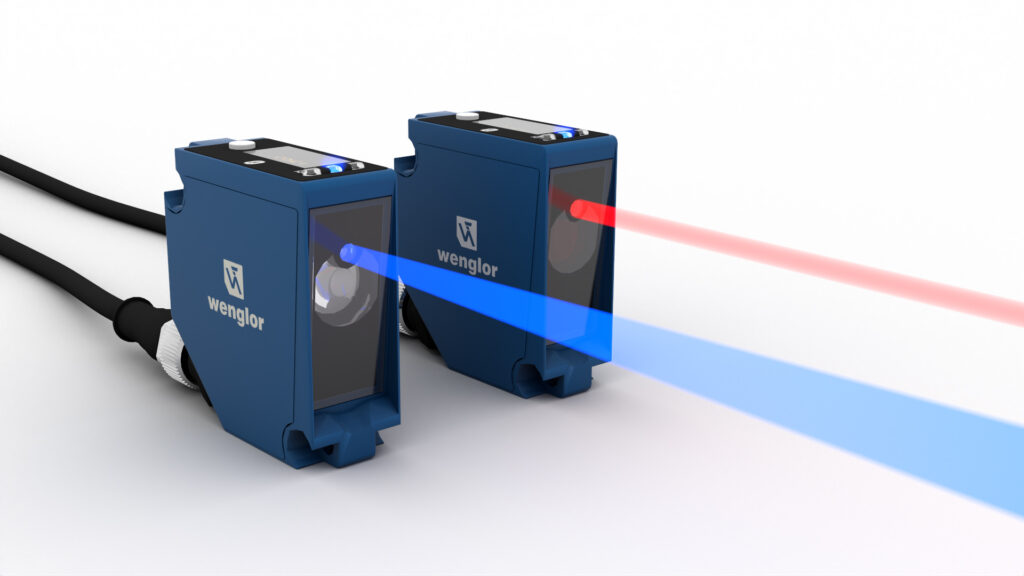

With the new P1PY21x series, the wenglor sensoric group is responding to this pressure to innovate and presenting the world’s first time-of-flight sensor that uses blue laser light. The specially developed BlueLine technology expands the well-known wintec family and opens up completely new fields of application.

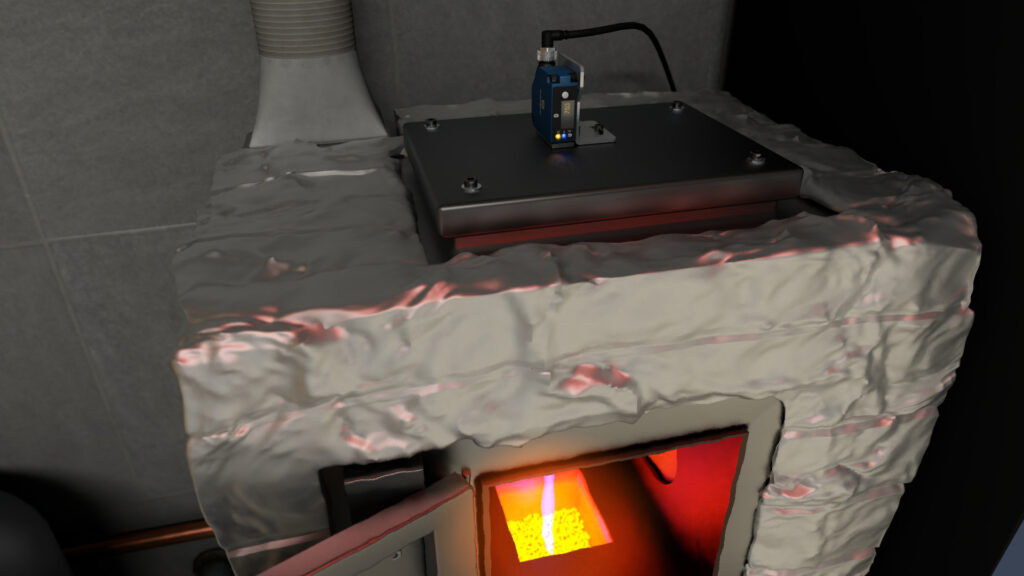

An example from the energy sector shows just how far-reaching the possibilities of this technology are. ToF sensors monitor the combustion process in pellet stoves. Only if the sensors can precisely detect how much ember is present can the control system optimally regulate the material supply. Red light sensors reach their limits here: The embers’ own radiation overlaps the signal, making measurements unreliable. Blue laser light, on the other hand, is less susceptible to such interference effects, provides stable measured values and enables efficient control of fuel consumption – which reduces operating costs and CO₂ emissions. This example shows just one of numerous application areas; from the metal and plastics industries to the packaging industry, the possible uses are many and varied.

This is made possible by the innovative BlueLine technology, which is based on a laser with a wavelength of 445 nm. While the red light version of the wintec family impresses with its long range, the short-wave blue light penetrates much less deeply into the object surface, for example organic objects, which means it is reflected in a defined manner and can be evaluated more precisely. With hot and glowing materials that radiate in the red to infrared range, red laser light also lies precisely in the interference range. The sensor signal is superimposed and the measurement can be falsified. Blue laser light, on the other hand, is far outside the inherent thermal radiation of such surfaces. The signal remains stable and free of interference, enabling reliable detection even in the metal industry, where red-hot workpieces need to be detected. This achieves more stable measurement results on dark, shiny, organic, glowing or (semi-)transparent materials. An integrated special filter additionally reduces interference from highly emitting objects. Laser class 2 ensures safe operation in industrial environments.

Not only the light color, but also the shape of the light spot makes a decisive contribution to the performance of the time-of-flight sensors. Instead of a dot-shaped laser, wenglor has introduced a laser line. This allows the sensor to detect not only individual points, but complete surface areas. Here, too, the development was geared towards industry practice, as this feature delivers significantly more stable results without measurement dropouts, especially on uneven surfaces, objects with breakouts, holes or grid structures, which proves advantageous when monitoring the fill level of bulk material, for example. Injection-molded plastic parts or other granular materials are filled into material bunkers and then fed individually to the next production step. Continuous fill level monitoring of these bunkers is just as crucial for a smooth production process as monitoring the height of the glowing bed in pellet ovens. The linear laser provides precise distance values even on irregularly filled or sloping surfaces and detects bunkers of different sizes and shapes thanks to its large measuring range. In this way, bottlenecks are avoided, material feeds are optimally controlled and production processes are stabilized.

In addition, the wintec with blue light has several intelligent functions that go beyond pure distance measurement. The intensity evaluation forms the basis for analyzing the reflected luminous intensity. This allows production steps to be monitored in a targeted manner and quality defects to be identified at an early stage. The integrated speed measurement records movements without contact and independently of the material or surface. This enables wear-free evaluation even over long distances. Another feature is the dynamic step detection. It does not detect the absolute distance, but reacts to changes in distance. This means that objects can be reliably detected even on varying surfaces or if the sensors are misaligned.

The fact that wenglor is now presenting the world’s first ToF sensor with blue laser light is no coincidence, but the logical continuation of a long history of development. In recent years, the company has repeatedly provided impetus in time-of-flight sensor technology: with the smallest time-of-flight sensor of its time, with the first stainless steel version for hygienically sensitive environments or with the introduction of Bluetooth in this sensor category. What all innovations have in common is a close focus on real requirements. They were always based on specific practical problems, from difficult surfaces to hygiene requirements and user-friendliness. The new blue light generation continues this line consistently and shows how the combination of the tried and tested and the new enables progress. The technical basis continues to be Dynamic Sensitivity technology, which has characterized the performance of the wintec family for years. This involves emitting very short laser light pulses in the nanosecond range, the signals from which are statistically evaluated to determine the distance value to the object. This approach ensures measuring ranges of up to 100 meters with a reproducibility of up to three millimeters, even under challenging conditions. In addition, the wintec with blue light is insensitive to ambient light up to 100,000 lux, so that the signal quality remains consistently high even in bright environments or with strong background radiation.

This means that the P1PY21x series is also suitable for outdoor applications. Transparent object detection opens up a further field of application. Thanks to the powerful signal processing, even very weakly reflective or transparent materials are reliably detected, which is a common challenge in the packaging or food industry, for example. Thanks to the high-performance IO-Link interface with COM3, the recorded process data can be transferred to the controller with minimal cycle times, which optimizes its use in automated processes. Thanks to the robust design with protection class IP68, the ToF sensors are particularly resistant to dust and liquids. They function even at extreme temperatures from minus 40 °C, meaning they work reliably in cold stores or alpine regions.

In addition to its measurement performance, the P1PY21x series also impresses in terms of user-friendliness. A high-contrast OLED display enables intuitive operation directly on the device. Even in unfavorable lighting conditions or in cramped installation situations, the indicator remains easy to read. The menu navigation is logically structured and all important settings can be accessed in just a few simple steps. This saves time during initial start-up, maintenance or in the event of a sensor replacement. The integrated Bluetooth interface provides even more flexibility. Sensor parameters can be transferred and adjusted wirelessly via the weCon app, which makes handling easier in installations with many devices or in hard-to-reach installation locations.

The combination of BlueLine technology, Dynamic Sensitivity and practical operation makes the P1PY21x series a solution that has proven itself in both classic and new industrial scenarios. It delivers precise and reliable results even on challenging surfaces, remains insensitive to interference and is easy to integrate thanks to modern interfaces. This makes the sensor a versatile tool for a wide range of industries, from the metal industry and plastics processing to the packaging and food industries. At the same time, this development demonstrates a basic principle that has characterized wenglor for years: Innovation arises where real problem areas in industry are recognized and technically solved. Sensors such as the P1PY21x series are key technologies for sustainable, resource-saving production. They enable more precise control, minimize waste, increase energy efficiency and thus help to make industrial processes fit for the future. In times of resource scarcity and growing pressure to automate, these are decisive factors. This makes it clear that the use of blue light in time-of-flight technology marks an important development step that makes existing applications more reliable, opens up new potential and creates space for completely new scenarios.

Job title