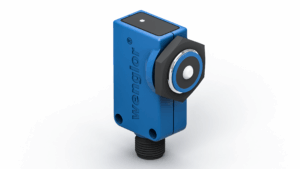

Precise, compact and easy-to-install sensors are crucial in industrial automation. The R format from wenglor combines the advantages of a round format and cubic housing so that photoelectronic sensors and ultrasonic distance sensors can be used flexibly in automatic machines or production systems. In this article, we show how the R format works, how it is mounted and what practical applications are possible.

The R format from wenglor is a hybrid sensor housing format that combines the advantages of a round format with a compact cubic housing. This format was specially developed to enable high flexibility when integrating into machines, automatic systems and production plants.

Thanks to the compact housing with vertical plug outlet, the sensors only require a shallow installation depth, which makes installation in confined areas easier. At the same time, the R format allows simple, tool-free installation: the sensor is simply inserted through a hole and fixed from the other side with a nut.

The R format is versatile and supports different operating principles, including reflex sensors, universal retro-reflex sensors and special retro-reflex sensors for transparent objects. Both photoelectronic sensors and ultrasonic distance sensors are available in this format.

The R format thus enables precise and reliable sensor integration with minimal space requirements.

The R format impresses with its simple installation:

Thanks to these properties, the sensors can be quickly integrated into machines or automated systems without the need for complicated adjustments.

The video shows two installation types of a P1R sensor in detail and illustrates how easy it is to install.

The sensors in R format are versatile:

Reflex sensor

Detects objects or hands without contact, even with highly reflective backgrounds.

Universal Retro-Reflex Sensors

Can be used universally, especially for transparent objects such as glass, PET or foiled packaging.

Ultrasonic distance sensors

Ideal for distance measurement and level control.

This flexibility makes the R format the perfect choice for machine construction and industrial applications.

In the food industry, precise fill level monitoring is crucial in order to comply with quality standards. Retro-reflex sensors in the R format can be used to reliably monitor the fill level of packaged food in checkweighers.

Touchless hand cleaning stations in the food industry or in public areas benefit from reflex sensors with background suppression in R format.

Installed underneath the taps, the sensor reliably detects hands and automatically activates the water jet, soap dispenser or hand dryer. This not only improves hygiene, but also reduces the consumption of water and soap.

The sensors are particularly practical because they can be mounted flexibly and have a compact design, allowing them to be easily integrated into existing fittings. This allows highly frequented areas to be automated efficiently and hygienically.

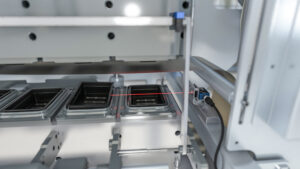

Precise positioning is crucial before trays are sealed with film. Retro-reflex sensors in the R format with laser light are attached to the side of the conveyor belt to detect the top edge of the trays.

The fine laser beam ensures that only correctly positioned trays are processed further. If a tray is too high, this is detected immediately and the sealing process is adjusted or stopped.

This application demonstrates the strength of the R format in automated production processes where precise, fast and reliable sensors are required to avoid production errors and increase efficiency.

The R format of wenglor sensors combines flexibility, easy mounting and precise sensor technology. Whether for fill level control, hand detection or tray position monitoring – these sensors are ideal for integration into automatic machines and production systems.

Job title